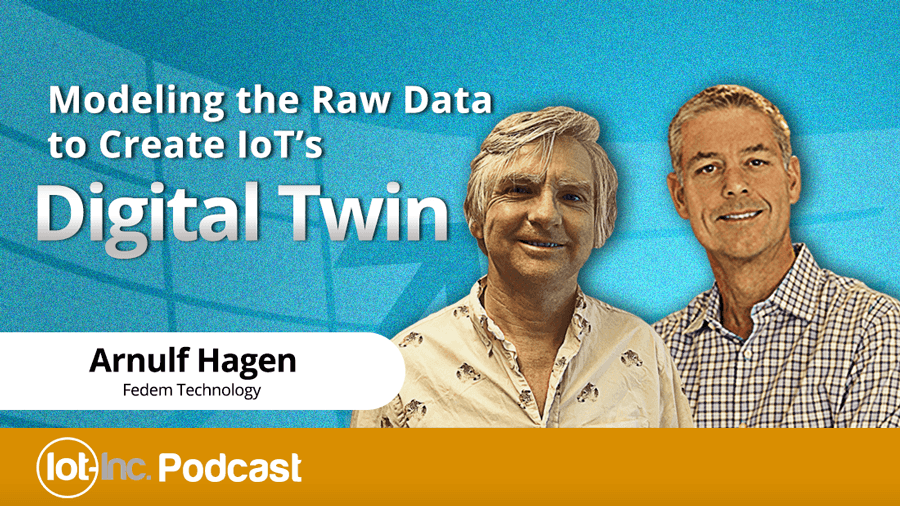

07 Jul Modeling the Raw Data to Create IoT’s Digital Twin

Episode 85

The reason the digital twin, or software-defined product, as I prefer to call it, is the most important IoT tech, is because it’s the basis for the unique functionality possible from using the Internet of Things. Going beyond smarts or connectivity, it is this unique functionality that creates value, enough value that results in a profitable IoT product. In this episode of the IoT Business Show, the second in a series on the digital twin, I speak with Arnulf Hagen about the underlying models of the digital twin, and the high-level ways you can use them to create value.

In this episode of the IoT Business Show, the second in a series on the digital twin, I speak with Arnulf Hagen about the underlying models of the digital twin, and the high-level ways you can use them to create value.

Arnulf is Managing Director of SAP-owned Fedem Technology, as well as Chief Product Owner in SAP. He is responsible for the development of physics-driven, high-fidelity, digital twins. He has worked the last 15 years as both as entrepreneur and executive manager.

The software-defined product consists of three parts. It starts with the data – both the raw data from sensors and external systems, and the meta data that gives it context. Second, we have the model. The model is developed to represent the raw data in a form that is computable. Then there is the application. The application is the original code developed to create functionality for the product. In a sense, it is the simulation environment that is used to execute the model within. Key for choosing your model development environment is to choose a toolset whose underlying mathematics used to represent the models are representative of the phenomena you are trying to simulate with your product. Not all modeling environments, in this sense, are created equal.

In the IIoT the software-defined product, or digital twin as it’s referred to here, is used in progressively more sophisticated ways. First for asset optimization, by using it for equipment health checking, and then for failure and maintenance modeling. Then it steps up a level and is used for operational optimization – so that’s maximizing your classic, asset utilization and operational efficiency, both of which have an affect on the bottom line.

Here’s What We’ll Cover in this Episode

- Physics-driven digital twins using finite element and Newtonian physics solvers.

- The different forms of data that represent the digital twin.

- Virtual sensors.

- Using the digital twin to go backward and forward in time.

- Using physics to reach a more accurate model of the digital twin.

- The need for statistical methods to augment the physics-driven digital twin.

Mentioned in this Episode and Other Useful Links

Support this Podcast

If you have been enjoying this podcast, there are a few ways you can support it:

- Share it on social by clicking on the widget on the left or bottom of the page.

- Click here to open iTunes and leave a one-click review or write your thoughts.

- Consider becoming a Certified IoT Professional by enrolling in the ICIP online training program.

Ways to Subscribe to the IoT Business Show

Like what you hear? Subscribe to get each episode delivered to your device via iTunes, Spotify, Google Play, Stitcher Radio or RSS (non-iTunes feed).

Have an opinion? Join the discussion in our LinkedIn group

Would a physics-based finite element and Newtonian physics model properly represent your data?

Click here if you have an opinion on this podcast or want to see the opinion of others